Blog

Download our brochure

Stay informed

Flow regulators are essential components in HVAC systems, ensuring balanced and consistent airflow throughout the ductwork. By maintaining a stable air distribution, they optimize the performance and efficiency of ventilation systems, contributing to improved indoor air quality and energy savings. In modern HVAC systems, ensuring a constant and controlled airflow is crucial for maintaining optimal performance and energy efficiency. The RDR constant flow regulator from Anjos is designed to meet these requirements effectively. By maintaining a steady flow rate despite variations in pressure, the RDR enhances system reliability and overall air quality. This article delves into the features, applications, and benefits of the RDR, illustrating its significance in contemporary ventilation solutions.

.webp)

Understanding Flow Regulators

A flow regulator is an aeraulic element placed inside ventilation or air-conditioning ducts. It is calibrated to the requested airflow and maintains a constant flow over a wide pressure range. Flow regulators can be used in both extraction and supply air ducts, ensuring a balanced and efficient HVAC system.

Understanding The Functionality Of The RDR Constant Flow Regulator

The RDR constant flow regulator operates by adjusting to varying pressure levels within the ductwork to maintain a consistent airflow. This adaptability is essential in environments where pressure fluctuations are common, ensuring that the ventilation system continues to perform efficiently and reliably. Key aspects of the RDR's functionality include:

- Pressure range: Operates effectively within 50 to 250 Pascals.

- Material: Made from durable plastic classified as M1 with a temperature tolerance up to 60°C.

- Installation: Simple interlocking system for both vertical and horizontal ducts with a sealing lip for airtight implementation.

By maintaining a stable airflow, the RDR helps to balance ventilation systems, reduce energy consumption, and enhance the longevity of HVAC equipment.

How Flow Regulators Work

The mechanism of a flow regulator involves a flap that adjusts the cross-sectional area of the air passage based on pressure variations upstream and downstream of the regulator:

- When the pressure difference increases, the flap reduces the air passage section.

- When the pressure decreases, the flap opens wider.

Flow regulators are factory-calibrated to the requested airflow but can be adjusted on-site as needed. For example, the RDR model includes scale markings on the front side for precise adjustments. The return spring ensures the flap returns to its set position, maintaining consistent airflow.

Types of Flow Regulators

There are several types of flow regulators, each designed for different pressure ranges:

- Low Pressure (RDR LP): 20 to 100 Pa

- Standard (RDR): 50 to 250 Pa

- High Pressure (RDR HP): 150 to 600 Pa

Applications Of The RDR In Various HVAC Systems

The RDR constant flow regulator is versatile and can be implemented in various HVAC settings. Its applications include:

- Commercial buildings: Ensures consistent ventilation in office spaces, retail centers, and other commercial environments.

- Industrial facilities: Maintains proper airflow in manufacturing plants, warehouses, and other industrial sites.

- Residential settings: Enhances air quality and comfort in homes and apartment buildings.

These applications demonstrate the RDR's flexibility and efficiency in different scenarios, making it a valuable component in any HVAC system.

Installation Guidelines

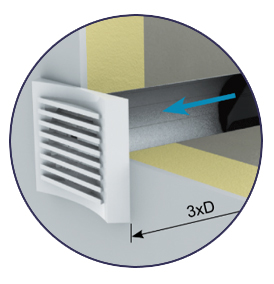

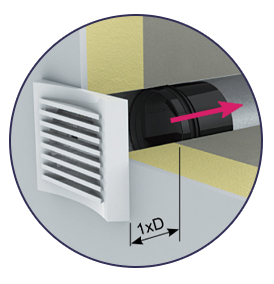

Proper installation is crucial for the optimal performance of flow regulators. They can be fitted into both vertical and horizontal ducts. In horizontal ducts, it is essential to follow the "DOWN" sign indicated on the product. Additionally, ensuring a minimum distance between the regulator and the diffuser is necessary:

At least three diameters in blowing mode

The flow regulator is mounted by a simple interlocking system inside the vertical or horizontal duct. In a horizontal duct, respect the DOWN direction indicated on the front of the regulator. A lip seal provides sealing.

Do not handle or press on the mobile flap (regulating element) during implementation. The direction of the air flow indicated on the cuff must be followed.

At least one diameter in extraction mode

When the regulator is associated with an air diffusion vent, the minimum distance between it and the regulator must be at least one diameter in extraction and three diameters at the inlet vent.

An airtight seal is necessary to maintain efficiency, and the regulator should remain accessible for maintenance.

Maintenance and Testing Standards

Regular maintenance of flow regulators ensures their long-term performance. The regulators are tested according to specific standards to ensure their reliability and efficiency:

- NF E 51-776-2: Aeraulic characteristics

- NF EN ISO 3741 and NF ISO 5135: Sound power levels

These tests confirm that the flow regulators meet stringent requirements, ensuring their effectiveness in various HVAC applications.

Key Benefits Of Using The RDR Constant Flow Regulator

Implementing the RDR in an HVAC system brings several notable advantages:

- Energy efficiency: By maintaining a constant flow, the RDR helps reduce the energy consumption of ventilation systems.

- Improved air quality: Consistent airflow prevents the buildup of pollutants, ensuring a healthier indoor environment.

- Easy maintenance: The RDR's design facilitates simple and regular maintenance, contributing to its long-term reliability.

- Cost-effectiveness: Enhancing system efficiency and reducing energy usage translates to lower operational costs.

These benefits highlight the RDR's role in promoting sustainable and efficient HVAC system performance.

Innovative Features

Modern flow regulators come with several innovative features that enhance their functionality:

- Adjustable flow settings: Allows for on-site fine-tuning to meet specific airflow requirements.

- Integrated noise dampening: Reduces operational noise, improving the acoustic comfort of indoor environments.

- Compact design: Facilitates easy installation in confined spaces without compromising performance.

Conclusion

Flow regulators play a vital role in maintaining balanced airflow in HVAC systems, ensuring energy efficiency and optimal indoor air quality. Understanding their function, types, installation, and maintenance is crucial for engineers, contractors, and builders looking to enhance the performance of ventilation systems. By integrating advanced features and adhering to proper installation and maintenance guidelines, flow regulators can significantly improve the effectiveness of HVAC systems across various applications. The RDR constant flow regulator from Anjous is a pivotal component for modern HVAC systems, ensuring stable and efficient airflow management. Its adaptability to pressure variations, easy installation, and broad applicability make it an ideal choice for various settings. By enhancing energy efficiency, improving air quality, and reducing maintenance needs, the RDR significantly contributes to the optimization of HVAC systems, affirming its importance in contemporary ventilation technology.